Wooden Hanger High-Speed Automatic Painting Production Line

- Product Information

Wooden Hanger High-Speed Automatic Painting Production Line is an advanced production equipment specially used for surface spraying of wooden hangers. The wooden hanger high-speed automatic painting production line greatly improves the spraying efficiency and quality through a series of highly automated equipment and process flows. Its appearance not only greatly improves the production efficiency of wooden hangers and reduces production costs, but also improves the appearance quality and consistency of products. It enables wooden hanger manufacturers to better meet the market demand for high-quality, personalized products and enhances the market competitiveness of enterprises.

The high-speed automatic painting and spraying production line for wooden hangers breaks the shackles of the industry, completes the painting of varnish and black paint at one time, and completes two primers of white paint, and increases the efficiency of the electrostatic line from 30,000 pieces per day by 10 people to 60,000 pieces per day by 2 people, which completely completes a revolution and transformation of technology and efficiency. WECAN Intelligence only produces high-quality products!

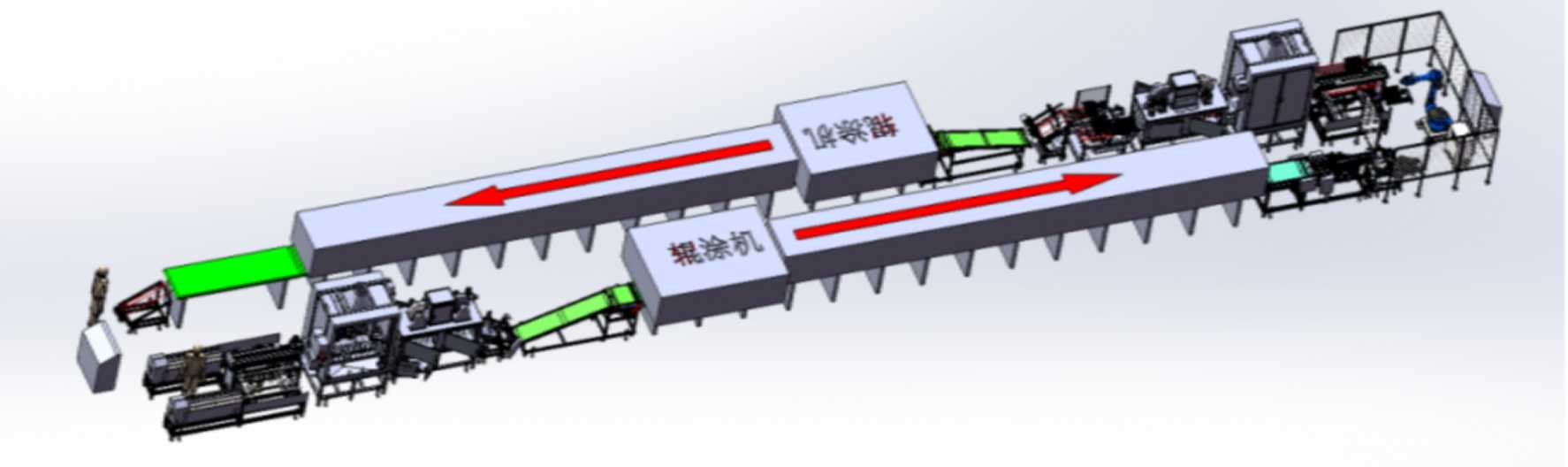

Production line components:

1. Automatic blank feeder (back)

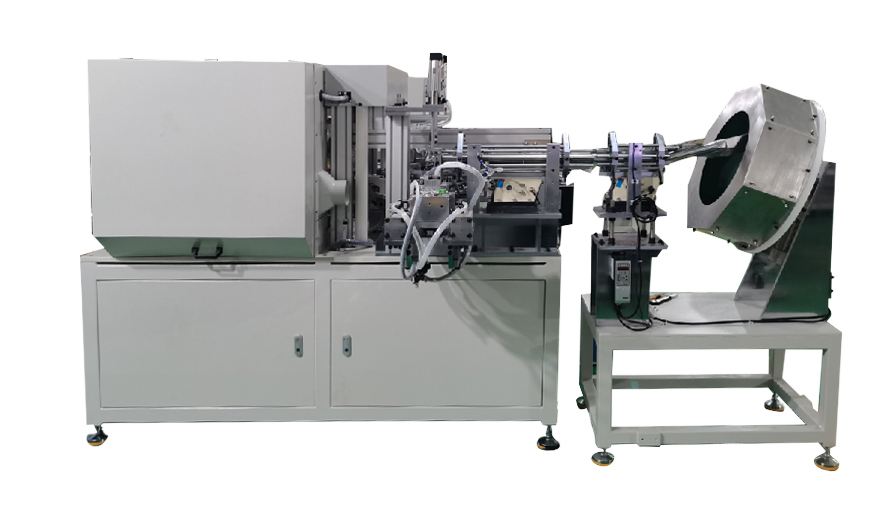

2. Automatic back spraying for wooden hangers

3. Automatic drying machine

4. Automatic hanger flipping machine

5. Surface roller coating machine for wooden hangers

6. Automatic drying machine for wooden hangers

7. Automatic material collecting machine for wooden hangers

8. Robot automatic transfer

9. Automatic blank feeder (bottom)

10. Automatic bottom spraying for wooden hangers

11. Automatic drying machine

12. Automatic hanger flipping machine

13. Surface roller coating machine for wooden hangers

14. Automatic drying machine for wooden hangers

15. Automatic material collecting machine for wooden hangers

Equipment advantages:

1. Highly information-integrated

As a fully automated coating equipment for wooden hangers with high information integration, it realizes the automatic control of the entire coating process from hanger loading, spraying, drying to unloading. Through advanced computer systems and sensor technology, the equipment can monitor various parameters in the production process in real time, such as paint flow, spraying pressure, hanger position, etc., to ensure the stability of spraying quality and production efficiency. This high degree of information integration not only improves the controllability and stability of production, but also provides rich data support for the production management of enterprises, facilitating the optimization of production plans and quality traceability.

2. Patent technology guarantee

The production line has applied for 1 invention patent and 2 utility model patents. These patented technologies cover spraying process, equipment structure, control system and other aspects, reflecting its leading position in technological innovation. The application of patented technology not only improves the performance and reliability of the equipment, but also provides users with unique competitive advantages, making them stand out in the fierce market competition. For example, some patented technologies may involve special spray head designs that can achieve more uniform and efficient paint spraying, thereby improving product quality and production efficiency.

3. Process innovation and subversion

It has brought revolutionary and subversive progress to the hanger painting process, and completely changed the traditional manual spraying or semi-automatic spraying mode. Traditional spraying methods have many problems such as low efficiency, unstable quality, and high skill requirements for operators. This production line solves these problems through a fully automated design. It can complete the spraying task with extremely high precision and speed, making the surface coating of the hanger uniform and smooth, and greatly improving the quality, setting a new benchmark for the painting process of wooden hangers.

4. Significant reduction in staff and efficiency

Compared with traditional painting methods, this production line can reduce staff by 80%. Traditional painting workshops often require a large number of manual operations, including loading, spraying, inspection and other links, while automated production lines only require a small number of operators to monitor and maintain equipment. This not only reduces the company's labor costs, but also reduces quality fluctuations caused by differences in personnel operations, and improves production stability and consistency.

5. Significantly shortened production cycle

It can shorten the production cycle by more than 40%. Traditional painting processes are slow due to their reliance on manual operations, and there is a lot of waiting and coordination time between different processes. The automated production line greatly reduces the waiting time in the production process and improves production efficiency through an efficient conveying system and continuous spraying process. For example, the equipment can complete the loading, spraying and drying of hangers in a short time, making the entire production process more compact and efficient, thereby shortening the product delivery cycle.

6. Site occupation and space optimization

The equipment occupies only 220 square meters, which can save 80% of the site compared to traditional painting workshops. Traditional painting workshops occupy a large area due to the need to set up multiple operation areas, paint storage areas, drying areas, etc. The automated production line adopts a compact layout design, integrating various functional modules in a smaller space, which not only saves space, but also makes the production process more centralized and efficient. This space optimization is of great significance to the factory layout and production planning of the enterprise, especially when land resources are limited, it can save a lot of costs for the enterprise.

7. Reduce management costs and personnel dependence

The dependence on skilled employees is 0, which greatly reduces management costs. Traditional painting processes require a large number of skilled workers to ensure the quality of spraying. These workers need long-term training and experience accumulation to master the operating skills. The automated production line does not need to rely on skilled employees, but only requires operators to have basic equipment operation and maintenance knowledge. This not only reduces the company's dependence on human resources, but also reduces the quality risks and management costs caused by personnel turnover, making the company's production management simpler and more efficient.

8. High efficiency and ease of operation

The efficiency is as high as 60,000 pieces/unit/shift, and the single-shift output is 60,000 pieces/shift/2 people, and only 2 operators are required. This high production efficiency is due to the automated design of the equipment and advanced spraying technology, which can complete a large number of hanger painting tasks in a short time. At the same time, the equipment is simple and convenient to operate, easy to manage on site, and the centralized material collection and release design makes logistics smoother, further improving production efficiency. Operators only need to perform simple operations according to the equipment's operating procedures to achieve normal operation of the equipment, without the need for complex operating skills and experience accumulation, which greatly reduces the company's operating difficulty and management costs.