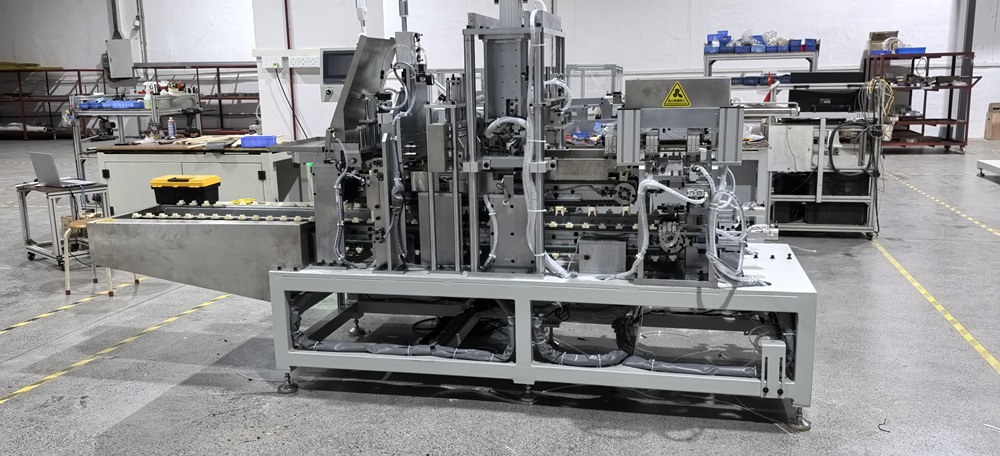

Trouser Clip Hanger Automatic Assembly Machine

- Product Information

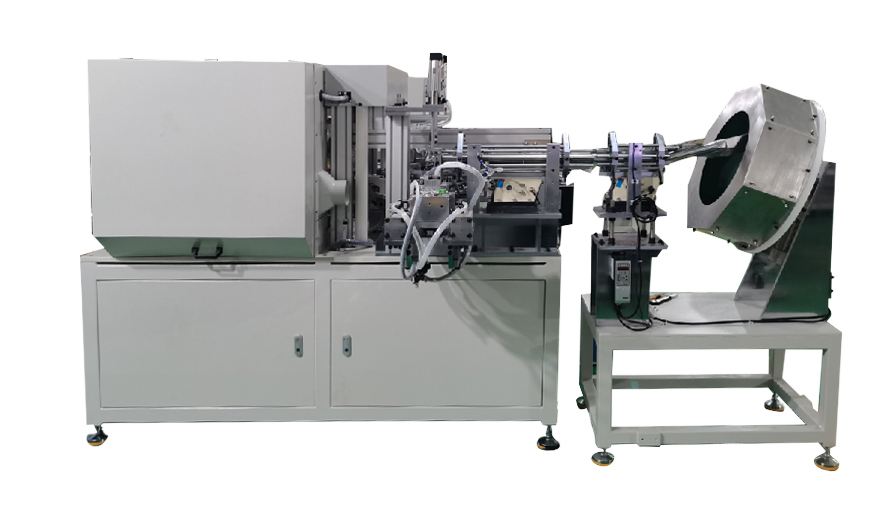

Trouser clip hanger automatic assembly machine is a kind of equipment specially used for automatic assembly of trouser clips and hangers. In the clothing production industry, trousers usually need to be fixed on hangers by clips for hanging, display and transportation. In the past, this work was mostly done manually, which was inefficient and prone to problems such as loose clamping. This machine realizes the fast and accurate assembly of trouser clips and hangers through advanced mechanical design and automatic control technology. With the continuous improvement of the clothing industry's requirements for the degree of production automation, the application of trouser clip hanger automatic assembly machine is becoming more and more extensive. It provides strong support for the modernization of clothing production enterprises, helping enterprises to improve production efficiency, reduce costs, improve product quality, and enhance their competitiveness in the market.

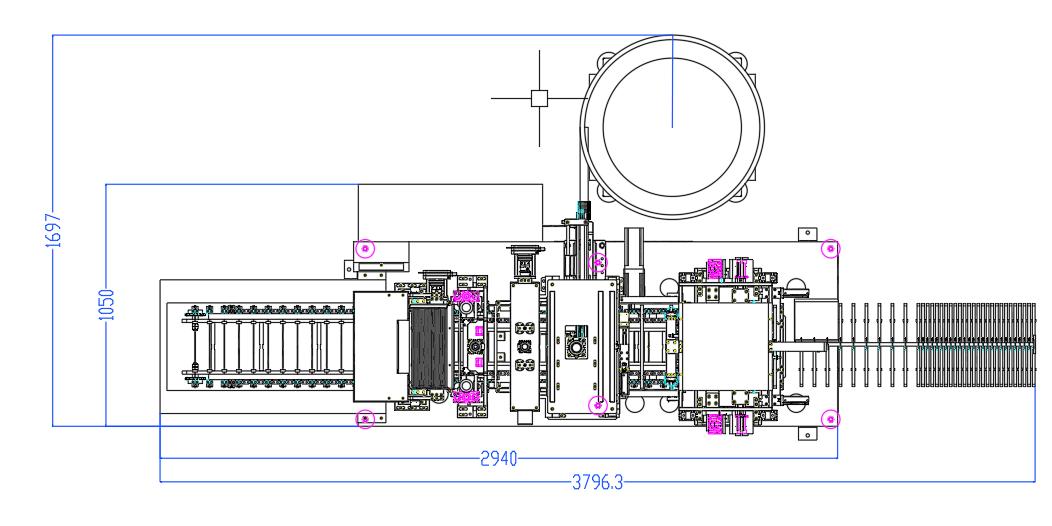

Equipment parameters:

1. Equipment layout: L2930*W1520*H1300mm

2. Equipment weight is about 2000KG

3. Air pressure 0.5±0.1MPa

4. Voltage three-phase 380V, power about 6KW.

5. Equipment design production efficiency 5S/piece.

6. Personnel required: 1 person/shift

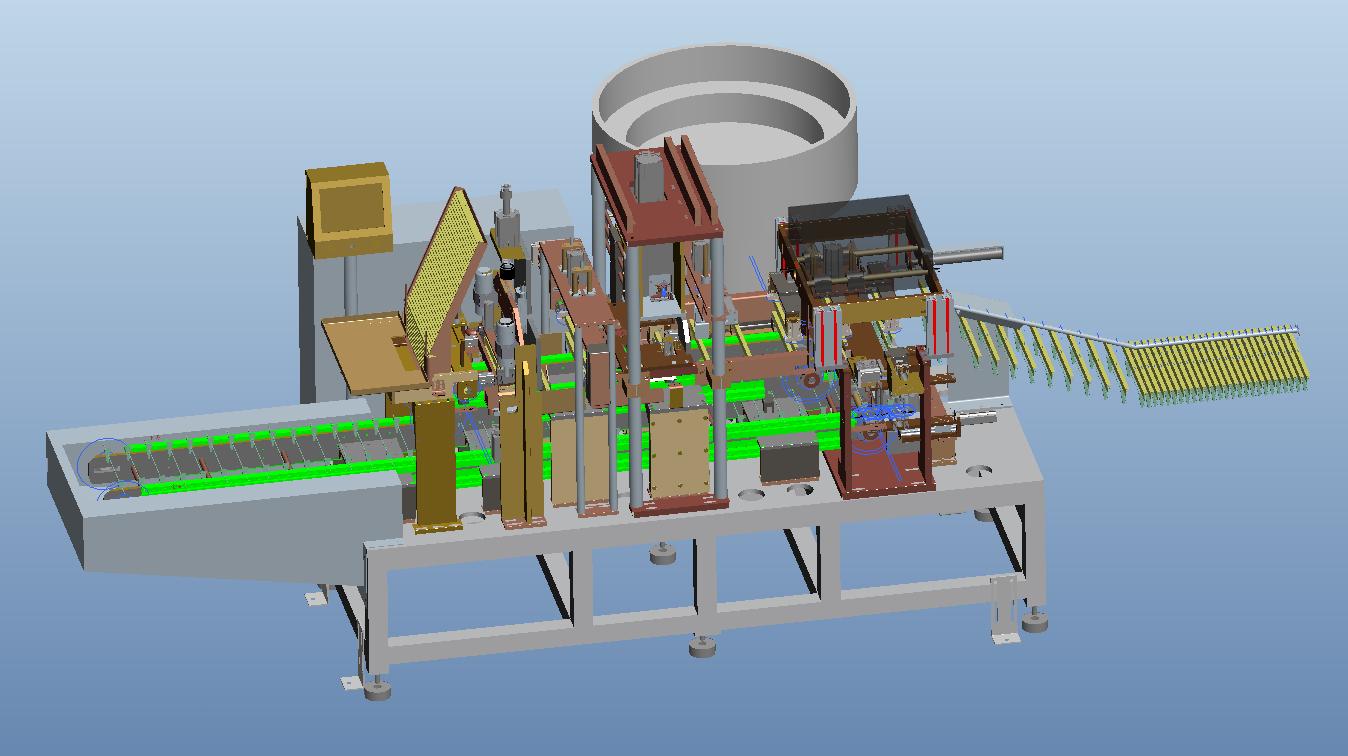

Detailed explanation of equipment station functions:

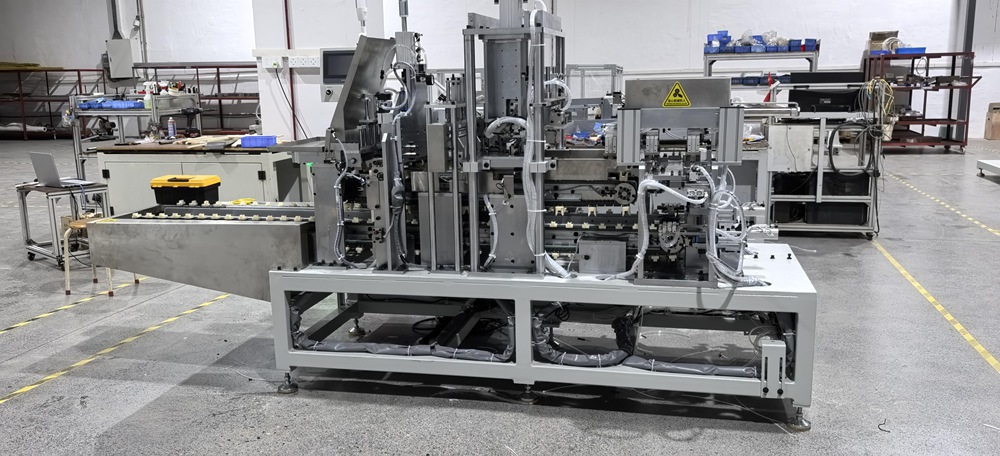

1. Linear rod feeding line: Because there are two clips on the linear rod, the position and angle of the clips are uncertain. To ensure the stable operation of the equipment, this solution designs the linear rod for manual feeding, and can feed no less than 12 pieces at a time.

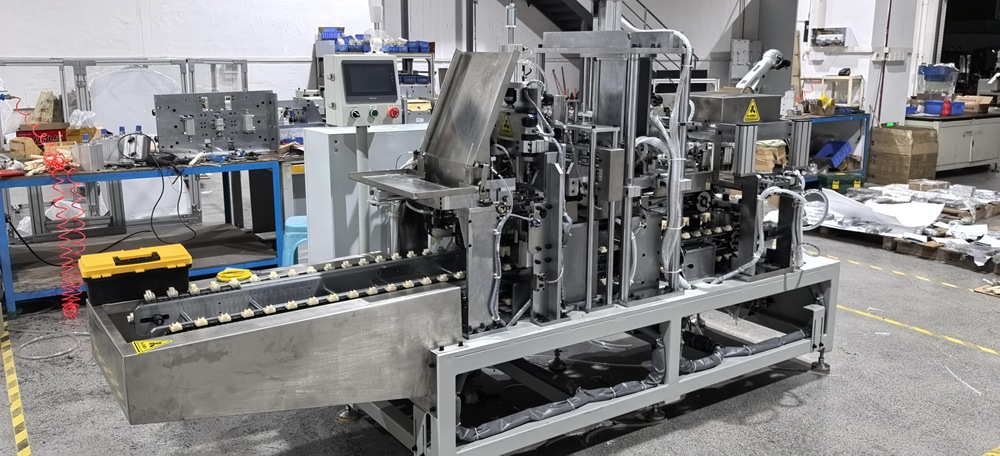

2. Wood storage bin: Manual feeding, about 50 pieces of material can be stored at a time.

3. Wood conveyor line: After the wood is separated from the storage bin, it is fed by the wood conveyor line.

4. Drilling double holes in wood: Position the wood and drill holes by two power heads.

5. Turn the wood upside down: After the wood is drilled with double holes, turn the wood upside down, with the single hole facing up and the double hole facing down.

6. Clothes hook vibration plate and direct vibration mechanism: Clothes hook uses vibration plate to store materials and direct vibration to feed and divide materials.

7. Clothes hanger positioning and clothes hook installation: After the clothes hook is inserted, the hook needs to be rotated 90 degrees.

8. Clothes hanger positioning and clothes hook installation: Position the wood (the previous process must ensure that the drilling hole is centered) and insert the clothes hook.

9. Hanger positioning and linear rod installation: The linear rod is fed through the feeding line, and the clamp grabs the head of the linear rod and positions the head of the linear rod. At the same time, the wood is positioned to ensure that the double holes of the wood and the two ends of the linear rod are aligned, and then the linear rod is inserted into the double holes of the wood.

10. Trouser clip unloading.